Cold room Solutions for Blood Sample Preservation in Nigeria

Cold room is a room in which a low temperature is maintained. It is meant for the storage of material for the purpose of preventing the material from deterioration. Generally speaking, the lower the holding temperature, the longer is the period of safe keeping of the material concerned. Hence, storage temperature is the most important single factor affecting the storage/shelves life of an item/produce.

This write up will focus mainly on the great relevance of cold room to the preservation of blood sample. Like any other fluid or tissue sample, whole blood can be most effectively analyzed when its integrity is maintained throughout collection, processing and storage. But how do you maintain the quality of a whole blood sample when considering long term storage? What happens when a sample is not handled properly? This we shall focus our attention on .Firstly, let us look at the composition of the whole blood sample.

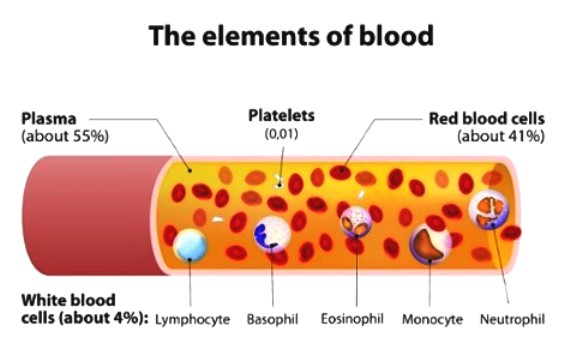

Whole Blood Basics

Whole blood samples are composed of several basic components: red blood cells, white blood cells, platelets and plasma. In addition, whole blood also contains an abundance of small vesicles (exosomes) containing RNA and proteins that serve as intercellular messengers.

In order to maintain the integrity of a whole blood sample, the collection, processing, and storage of blood components must take into consideration their future intended use post storage.

Blood components are typically isolated through centrifugation. After the desired blood components have been isolated, they can be placed into cryovials and stored in liquid nitrogen or mechanical freezers. We all may need blood in an emergency, and some of us regular transfusions. The purpose of a transfusion is to provide the blood component(s) that will improve physiological status of the patient. The collection of blood from donors may take place within the blood transfusion centre or hospital blood bank. It is also often collected from donors during mobile blood collection sessions. The blood is then taken to a laboratory for testing and processing into components and for storage and distribution as the need arises.

Storage

According to the University of California, Los Angeles, blood components should be stored as follows:

Red blood cells can be stored for up to 42 days at 1°C to 6°C, depending on additive.

Platelets can be stored at 20°C to 24°C for up to 5 days with constant agitation.

Plasma that is frozen at temperatures of -18°C or below within 8 hours of collection, platelets can be stored for up to 1 year.

However, for long term storage there are different best practices that should be closely followed. A spot of whole blood can be stored on commercially available filter paper at ambient temperatures, but only for a limited number of years and humidity must be controlled. When storing plasma and serum for an extended period of time, the recommended temperature is -80°C or below and all cellular components at -150°C or below.

It’s important to understand the proper mechanisms required to maintain your samples integrity throughout the handling process. The monitoring and maintenance of blood cold chain equipment is one major thing to consider and this rests on the personnel that has been trained and certified.

The Making of Blood Storage and Preservation Equipment

Blood refrigerators, plasma freezers and platelet agitators are the blood cold chain equipment used for the storage of blood components. Blood refrigerators and plasma freezers rely on refrigeration systems. Refrigeration (and Air-conditioning) is the process of removing heat from a confined environment until the desired temperature is attained, and then maintaining the air at this temperature range.

Whatever the design, size or purpose of the elements of a refrigeration system, the principles of operation remain the same. This section aims to provide you with an understanding of the equipment used to store blood components and the key elements of the refrigeration or temperature maintenance systems.

Refrigerant Gas

This is the fluid in a refrigeration system that changes from a liquid to a Vapor, and back to liquid, as it moves from one component of the cycle to the other. The most important aspect of the refrigerant gas is that it must be CFC-free as chlorofluorocarbons (CFCs) contribute to the depletion of the ozone layer in the earth’s atmosphere. All managers and users must

Ensure that they buy equipment with CFC-free refrigerant gas, and that existing CFC gas equipment is replaced according to the requirements of the Montreal Protocol (see Annex 1).

Refrigerant gases rarely need replacing if the equipment has been handled well in transit. However, it may happen that the gas escapes or becomes depleted. It is therefore important to identify a local source of the gas since, without it, the refrigerator or freezer ceases to cool the cabinet down.

Extreme care is needed to prevent refrigerant from coming into contact with your eyes, face or skin. Never let refrigerant spray on to your skin as frost bite or cold burn will result. Replacing the refrigerant gas requires a trained refrigeration expert.

The Compressor

The compressor is the heart of the refrigeration system. It compresses the refrigerant vapor and pumps the heat-laden refrigerant gas to the condenser. The compressor rarely breaks down, but if it does, the only Solution is to replace it with a new compressor or reconditioned unit. The major causes of failure of compressors are fluctuation in the voltage supply that affects the compressor motor, particularly at starting, when a considerable load of power is consumed. Replacement of the compressor should only be carried out by a refrigeration expert. The compressor is the most expensive part of the equipment.

The Condenser

The condenser releases heat from the refrigerant gas to the surrounding air. The condenser is easy to identify as it is usually made of steel or copper and is normally painted black. Condenser pipes are kept together by wire fins, which also help to increase the cooling surface area of the condenser. The condenser rarely fails. However, because of its crucial role in heat transfer, it needs to be kept clean and free of dust.

The Evaporator

The evaporator is the area that absorbs heat from the cabinet and its contents. The refrigerant gas enters the evaporator as a liquid and absorbs heat and flows out the other end as a vapor. The vapor flows into the condenser under a high pressure from the compressor as the cycle begins again. The evaporator rarely requires repair but needs to be kept clean.

The Thermostat

The thermostat is a device that senses temperature changes, and at a predetermined temperature activates or deactivates a mechanical or electric activity. Thermostats thus have “cut in” and “cut out” set temperatures. These predetermined temperatures may be permanently set in the factory, or may be adjustable by the user. The thermostat starts the compressor when the temperature inside the cabinet rises to a predetermined level, e.g. +5.0 °C, and stops it when the temperature

Inside the cabinet is reduced to a predetermined minimum, e.g. +2.5 °C. Blood bank refrigerators and plasma freezers have their thermostats set in the factory. Only a qualified refrigeration technician should carry out any adjustment to the thermostat.

Care of Refrigeration Equipment

The safety of blood cold chain equipment depends on its location and the care it receives, especially during transportation and installation. Always ensure that the equipment is safely handled. The heat loss from refrigeration equipment affects the ambient temperature of the room. This in turn means greater activity of the compressors to keep the temperature of the cabinets within acceptable limits. It is therefore important to en-sure a reasonable quantity and spacing of the equipment and to avoid the equipment being in sunlight or near heat-generating equipment.

Importance of Walk-in Cold rooms and Freezer rooms in Preservation of Blood Samples

Although there are currently no WHO minimum performance specifications for cold or freezer rooms, the information below is provided for users of this equipment. Walk-in cold and freezer rooms are storage fixtures that are available in a wide variety of sizes to suit every need. They are either permanently erected or of the knockdown type that can be moved. Very large installations are permanent and cannot be moved. Cold and freezer rooms are best constructed at

the same time at the blood transfusion centre, since they are expensive items whose positioning needs careful planning. The cooling mechanism of the equipment also uses CFC-free refrigerant gas. Cold rooms operate at between +2 °C and +6 °C, are ideal for the bulk storage of blood components and are therefore usually found at central blood banks or major regional centers.

Freezer rooms are generally constructed as cold rooms except that they have much thicker insulation and the cooling mechanism provides for temperatures below –30 °C. Ideally a freezer room is accessed through the cold room in order to minimize temperature change in the freezer. If the door of the freezer room opens directly to “open air” temperatures, there is a risk of a rapid temperature rise in the freezer room, resulting in the temperature alarm being triggered.

It is equally important to ensure that the door mechanism on the freezer is secured to prevent it opening into the cold room and freezing the blood. Ideally cold and freezer rooms have plastic sheeting against the inside of the door to assist with trapping cold air inside and preventing warm air entering the room. A dual cold and freezer room exists that is constructed in the same way as a freezer room, except that the thermostat of the refrigeration plant is adjustable to meet freezer or cold room purposes.

In addition, the exterior of the cabinet is made of galvanized metal or aluminum. The recommended internal lining is stainless steel. The doors of the cabinet are usually of the same construction as the box. Instead of insulation, the doors may have two or three dead air spaces arranged in such a way that they are airtight. Since a power failure will cut off the electricity supply, measures should be taken to ensure emergency lighting and alternative current to activate the panic button.

Ideal design features of cold rooms and freezer rooms

- Pre-set alarm at +1.5 °C and +5.5 °C (cold room) and at –25 °C (freezer room).

- Temperature Display Unit at 0.1 °C graduation.

- Audiovisual alarms: temperature out of range and power failure warning with battery back-up.

- Continuous Temperature Recorder: seven day chart with battery back-up.

- Shelving: to hold trays of blood packs (cold room) or plasma and cryoprecipitate packs (freezer room).

- Doors: door open lighting system and door open alarm system.

- Temperature Monitoring: Interface for Remote Temperature Monitoring.

- Alternate refrigeration or freezer plant with emergency automatic or programmed switchover of refrigeration systems.

- Safety latch on the inside of door to allow anyone trapped inside to get out and/or an alarm (panic button).

Preventive Maintenance, Care and Repair of Equipment

Blood cold chain equipment requires minimal maintenance if correctly installed and cared for. The routine preventive maintenance procedures recommended by the manufacturer must be observed in order to reduce the “down time” on the equipment. There is considerable variation in

the level and complexity of equipment used in the blood bank. Although it is thought that more sophisticated equipment requires less attention, the opposite is often true. All equipment needs regular maintenance, if only once a year for certain items, to ensure that it is working as efficiently and reliably as possible.

Basic care and preventive maintenance of blood Cold Chain Equipment and Accessories

+ Blood Bank Refrigerators and Freezers

Most faults on refrigerators and freezers are a result of poor care and maintenance by the user. We should take note of the following hints:

i) Do not push your appliance against the wall where the condenser part touches t he wall, thus preventing proper ventilation. It is recommended that you leave space behind your refrigerator/freezer to allow air to circulate freely and carry the heat away from the condenser.

ii) When defrosting, switch the appliance off and remove the plug. Never use sharp objects such as a knife to poke or dig ice from the freezer compartment, which could lead to punctures where upon refrigerant, is released. Most evaporators are made of aluminum, which is very soft and punctures easily. Replacement of the gas is costly.

iii) When transporting the equipment to another room or building, do not place the refrigerator on its back since oil from the compressor may be forced into the pipes. Stand it in an upright position to avoid disturbances of the gas circulation in the unit.

iv) Do not fill the refrigerator or freezer too tightly as this limits internal air circulation, causing uneven cooling and excessive running of the compressor, which could lead to burn out.

v) Ensure that the door seal gasket is sealed at all times, and do not adjust the thermostat or switch it off at night. It automatically regulates itself, switching itself on and off to keep internal temperatures constant within the preset range.

vi) When closing refrigerator doors, do not bang them shut, because the door gaskets will lose their magnetism and fail to close the confined space tight, resulting in overworking of the compressor.

vii) Doors should not be kept open for too long. Blood packs or plasma should be removed from or placed in the cabinet quickly.

viii) Make sure that the door switch is in good operating order. It should switch off the cabinet light when the door is closed.

ix) Only skilled personnel should undertake repairs, modifications or adjustments.

x) Temperature chart recorders should be changed when due, e.g. 24-hour or 7-day records. It is important to ensure the chart is in motion and the pen is tracing. The date of change should be written on the chart.

Consult DEKOOLAR NIGERIA LIMITED today to discuss your blood bank cold and freezer room. We have been providing best-in-class blood storage and preservation solutions for the Nigerian Healthcare Industry over the pas two decades.

- MANUFACTURING OF BLOOD BANK REFRIGERATOR AND MAINTENANCE.

- MANUFACTURING OF Walk-In Cold Room AND MAINTAINANCE.

- AIR CONDITIONERS SUPPLY ( INSTALLATION AND MAINTENANCE)

- ICE BLOCK MACHINE MANUFACTURER

- GENERAL HVAC & R SOLUTION PROVIDERS CALL DeKOOlar Today!